According to the "Interim Measures for the Acceptance of Environmental Protection upon Completion of Construction Projects" (National Environmental Regulation on Environmental Impact Assessment (2017) No. 4), after the completion of the project acceptance report, relevant information regarding the acceptance report should be made public. The completion environmental protection acceptance report for the project of Zhejiang Global Machinery Technology Co., Ltd. for the production line with an annual output of 8 million sets of powertrains is now publicly announced to solicit public opinions.

Public announcement period: June 1, 2020 - June 30, 2020 (20 working days). During the announcement period, the public can log on to http://www.sxglobal.net/cn to check the relevant content of the project acceptance report.

If the public has any opinions or suggestions regarding the environmental protection acceptance of this construction project, they can reflect them to the construction unit during the announcement period. Please leave your contact information (name, address, phone number) for timely responses and feedback.

View Details

23

2021.03

After years of effort, domestic brands have finally equipped their cars with our own transmissions, solving technical issues. The next step is to establish industrialization, and the development in this phase will face greater uncertainties. Foreign automotive automatic transmission companies are putting unprecedented pressure on the current domestic automatic transmission industry by lowering product prices or forming joint ventures with domestic vehicle manufacturers.

View Details

23

2021.03

Why do pure electric vehicles often use a single-speed transmission?

People who are used to gasoline vehicles generally know that for a car, the more gears the transmission has, the higher the car's value. For example, most ordinary models are equipped with 6-speed or lower transmissions, while luxury models typically have 8-speed, 9-speed, or even 10-speed transmissions. However, this logic does not apply in the realm of pure electric vehicles. The reality is that from low-cost small cars like Zhidou to high-end Teslas costing over a million, almost all pure electric vehicles use a single-speed transmission, commonly referred to as "electric vehicle single-speed transmission," also known as "single-ratio fixed gear transmission."

This transmission is something that many industry insiders do not actually consider a transmission; to put it simply, it is just a reducer. For instance, Tesla is equipped with a reducer that has a fixed gear ratio of 9.73 and does not provide shifting functionality.

Why do pure electric vehicles not use multi-speed transmissions? This is determined by the characteristics of the electric motor. Unlike an engine, an electric motor can output full power from 0 RPM without the issue of idling. Additionally, the RPM range of an electric motor is broader and higher, generally reaching over 7000-10000 RPM. The role of the reducer is to lower the motor's RPM and transmit power to the wheels. At the same time, the maximum output power of the electric motor can be maintained over a wide RPM range, which can basically cover various operating conditions encountered by the vehicle. Therefore, it only requires a fixed gear ratio reducer, without the need for a complex multi-speed transmission.

Electric vehicles use high-speed electric motors that are controlled by an electronic control system for speed regulation. The fixed gear ratio transmission can change the vehicle speed through different gear ratios. This structural disadvantage causes electric vehicles to have high energy consumption at startup, high motor RPM, and a single speed regulation function of the transmission. In high-speed driving conditions, it cannot reduce the motor RPM through a transmission with a gear ratio less than one in overdrive, and the single-speed transmission also limits the vehicle's top speed.

Moreover, the motor itself has an automatic speed-changing function. As long as the input power of the motor remains constant, it can automatically find an optimal balance point between output power and output torque without requiring you to control the RPM. This is determined by the inherent electrical characteristics of the motor, so there is no need to use a transmission for control.

View Details

23

2021.03

Independent brand auto parts suppliers are working hard to overcome the technical challenges of automatic transmission assembly and are struggling along the path of industrialization. Against the backdrop of needing industry support the most, the International Seminar on the Industrialization of Automatic Transmissions in China and the Development Forum of China's Gear Transmission Industry were held in Wuxi, Jiangsu, from August 11 to 12. This conference conveyed positive signals: all parties are taking action in their own ways to support the industrialization of independent automatic transmission.

View Details

23

2021.03

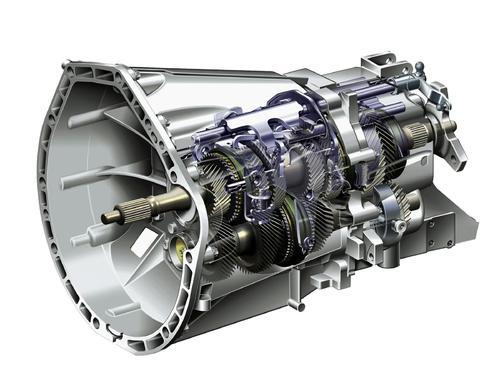

There are three common types of automatic transmissions in cars.

They are respectively the hydraulic automatic transmission (AT), the mechanical continuously variable transmission (CVT), and the electronically controlled mechanical automatic transmission (AMT). Currently, AT is commonly used in passenger cars and has almost become synonymous with automatic transmissions. AT consists of a hydraulic torque converter, planetary gears, and a hydraulic control system, achieving speed and torque changes through hydraulic transmission and gear combinations. Among them, the hydraulic torque converter is the most important component, composed of parts such as the pump wheel, turbine, and guide wheel, serving both torque transmission and clutch functions.

View Details

23

2021.03

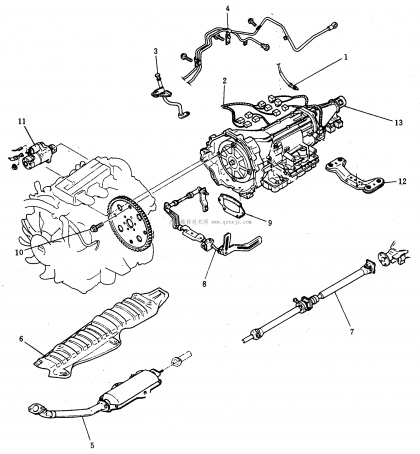

Steps for Disassembling and Breaking Down an Automatic Transmission

Steps for Disassembling and Breaking Down an Automatic Transmission

View Details

23

2021.03

An automatic transmission consists of five main components.

There are many brands and models of automatic transmissions, and their external shapes and internal structures vary. However, their composition is fundamentally the same, consisting of a torque converter and a gear-type automatic transmission.

View Details

23

2021.03

Automatic Transmission Maintenance Guide

An automatic transmission is a device that can automatically shift gears based on engine speed, as opposed to a manual transmission. There are three common types of automatic transmissions in cars: hydraulic automatic transmission (abbreviated as AT), continuously variable transmission (abbreviated as CVT), and electronically controlled mechanical automatic transmission (abbreviated as AMT).

View Details

23

2021.03

According to foreign media reports, BMW will establish a factory in Leipzig as a production base for high-voltage battery modules for BMW electric vehicles, in order to expand its electric vehicle component production capacity in Germany. BMW stated that it will invest over 100 million euros in battery production in Leipzig by 2022. Additionally, BMW will also produce the battery-powered i3 hatchback at this factory.

View Details

23

2021.03

Musk: Almost all components in Tesla's production are 75% automated.

Tesla CEO Elon Musk stated on Twitter that nearly 75% of the parts production in Tesla's manufacturing process is automated. Only the wiring harness and final assembly are primarily done manually, which accounts for less than 10% of the production cost.

View Details

23

2021.03